- This topic is empty.

-

AuthorPosts

-

2025-08-04 at 1:51 pm #86033

With the continuous growth of global energy demand, natural gas, as a clean and efficient form of energy, has become increasingly important for safe management of its production, transportation, and use. Pipeline systems and valve control in the natural gas industry are crucial for ensuring the stability and security of energy supply. Valve interlocking, as an advanced safety control technology, has been widely used in the industry to ensure standardized and safe valve operation and prevent accidents caused by misoperation. This article systematically introduces the application background, functions, types, and specific application cases of valve interlocking in the natural gas industry to help readers gain a deeper understanding of its importance.

1. Safety Challenges of Valve Control in the Natural Gas Industry

Natural gas, a flammable and explosive energy source, is transported through a complex pipeline network involving high-pressure, high-temperature, and diverse hazardous media. As a key component of pipeline systems, the safety of valves in opening and closing operations is directly related to pipeline stability and the safety of personnel and equipment.

In actual operations, valves often open or close incorrectly due to human error, improper operating procedures, or equipment failure, resulting in natural gas leaks, explosion risks, and even major safety accidents. Especially in situations where multiple valves are linked, valve operation must follow strict sequences and rules; otherwise, abnormal system pressure or disrupted fluid flow can easily result.

Therefore, effective management and safe control of valve operation has become a critical issue for safe production in the natural gas industry.

2. Introduction to the Valve Interlock System

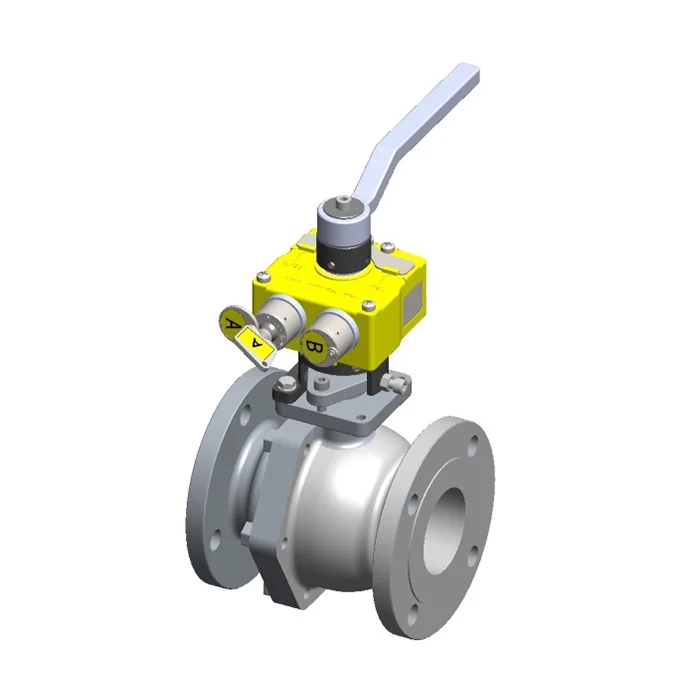

A valve interlock is a safety device that mechanically or electronically limits and controls the valve operation sequence. Its core function is to prevent valves from opening or closing without permission or in an unspecified sequence, eliminating safety hazards caused by human error.

A valve interlock system typically uses locks, mechanical linkages, or intelligent control units to interconnect the operating permissions of multiple valves. Only when the previous valve reaches a predetermined state can the next valve be unlocked or allowed to operate, ensuring that the valve opening and closing sequence complies with process and safety regulations.

3. Specific Applications of Valve Interlock in the Natural Gas Industry

In the natural gas industry, valve interlock systems are widely used in multiple critical processes, including natural gas transportation, pressure regulation, storage, and distribution. 3.1 Gas Pipeline Safety Management

Long-distance natural gas transmission pipelines typically have multiple valve nodes responsible for controlling the opening and closing and flow direction of pipeline sections. The valve interlock system can achieve the following safety controls:

Preventing incorrect valve openings and closings: Ensures valve operation follows the predetermined process and sequence to avoid cross-flow or abnormal pipeline pressure.

Emergency shut-off protection: In the event of an abnormality, the interlock system ensures safe and reliable operation of emergency shut-off valves, preventing the spread of accidents.

Maintenance isolation safety: During maintenance or repair, valve interlocks ensure that relevant pipeline sections are safely isolated to prevent accidental opening and danger.

3.2 Standardized Valve Operations at Pressure Regulating Stations

Natural gas pressure regulating stations are key nodes for regulating pipeline pressure. Standardized valve operation directly impacts accurate pressure control and system safety. The valve interlock system plays a crucial role in this:

Ensuring operational sequence: Pressure regulating stations involve multiple valves, including intake valves, bypass valves, and safety valves, and the interlock system ensures that the operational sequence complies with safety standards.

Preventing overpressure or underpressure caused by incorrect operation: Locking valves that do not meet safety requirements prevents incorrect operation from affecting system stability. Implementing Operational Permission Management: Interlocking mechanisms restrict unauthorized personnel from operating critical valves.

3.3 Gas Storage Facility Safety

Gas storage facilities store large quantities of natural gas, posing an extremely high safety risk. The valve interlock system ensures:

Gas tank inlet and outlet valve interlocks: Ensure that the filling and deflation valves cannot be opened simultaneously to prevent gas backflow and leakage.

Valve Open/Close Lockout Management: Physically lock critical valves to prevent accidental or unauthorized operation.

Emergency Rapid Response: Interlocking with the emergency shut-off system to rapidly close critical valves.

3.4 User-Side Pipeline Network Safety

At natural gas distribution stations and user terminals, valve interlocks ensure:

Distribution valve sequence interlocking: Ensure that multiple branch valves operate in a standardized sequence, ensuring user gas safety.

Preventing Accidental Leaks and Backflow: Interlocking devices restrict operation and reduce safety hazards.

4. Advantages of the Valve Interlock System

Improved Safety: Significantly reduces the risk of accidents caused by valve misoperation, ensuring the safety of personnel and equipment.

Standardized Management: Standardized valve operation procedures reduce human error and improve operational efficiency. Compatible with Automation and Digital Management: Modern electronic interlock systems can be connected to SCADA and DCS systems for remote monitoring and intelligent alarms.

Reduced Maintenance Costs: Preventing misoperation reduces equipment damage and maintenance frequency, extending equipment life.

Compliance with Regulations and Industry Standards: Meeting national and international safety standards facilitates safety certification.

5. Precautions for Implementing a Valve Interlock System

Accurately identify critical valves and operating procedures to ensure the interlock design meets process requirements.

Select interlock types and materials appropriate for the site environment, such as corrosion resistance and explosion-proof ratings.

Perform system integration and personnel training to ensure stable system operation and proper use.

Regularly inspect and maintain interlock devices to prevent failures caused by mechanical wear or electronic malfunctions.

With increasingly stringent safety management requirements in the natural gas industry, valve interlock systems, as a key technology for ensuring safe valve operation, play an irreplaceable and important role. Through the appropriate design and implementation of valve interlock systems, natural gas companies can not only effectively prevent safety risks but also achieve standardized and intelligent management of valve operations, providing a solid guarantee for the safe, stable, and efficient supply of natural gas.

As a professional valve interlock system manufacturer, we are deeply aware of the natural gas industry's stringent requirements for safe valve operation. Leveraging our extensive industry experience and advanced technology, our products offer not only high reliability and durability, but also flexible adaptation to diverse environmental and process requirements, helping natural gas companies achieve safe, standardized, and intelligent management of their pipeline networks. Choosing our valve interlock systems means choosing expertise, quality, and safety.

http://www.nudango.com

nudango -

AuthorPosts

- You must be logged in to reply to this topic.