- This topic is empty.

-

AuthorPosts

-

2025-08-04 at 5:08 pm #86039

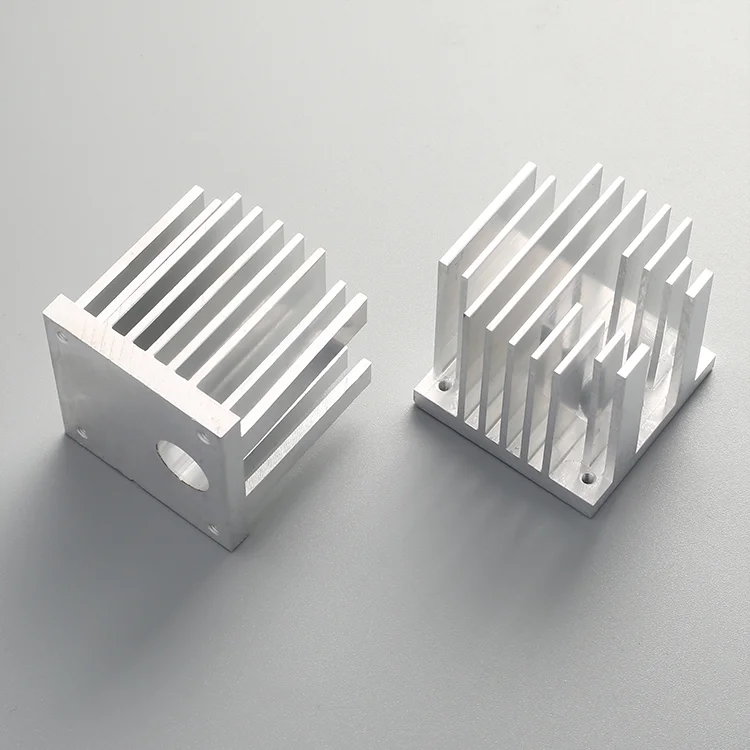

Aluminium heatsinks are widely utilized in industries ranging from electronics and automotive to LED lighting and renewable energy due to their excellent thermal conductivity, light weight, and corrosion resistance. The manufacturing process of these heatsinks typically begins with aluminium extrusion and is followed by CNC machining and surface finishing. In this blog post, as a high quality custom heatsink manufacturer, Vibo will share the CNC machining aluminum extrusion heatsink process flow, such as technical requirements and benefits.

Step 1: Aluminium Extrusion – Creating the Base Profile

Material Selection:

The process begins with the selection of high-quality aluminium alloys, most commonly 6061 and 6063. These alloys offer an ideal balance of thermal conductivity, mechanical strength, cost-efficiency, and corrosion resistance, making them perfect for thermal management applications.

Extrusion Process:

1. Billet Heating

The aluminium billet is heated to approximately 500°C, a temperature that softens the metal for plastic deformation without causing it to melt.

2. Die Extrusion

Once softened, the billet is pushed through a pre-designed die that determines the heatsink's cross-sectional shape. This die typically includes features for uniform, parallel fins and a solid base.

3. Cooling and Cutting

After exiting the die, the long aluminium profile is immediately cooled, usually via air or water quenching. Once solidified, it is cut to the desired lengths for further processing.

Output:

At this stage, we obtain a rough aluminium heatsink blank with consistent fin patterns—either straight, cross-cut, or custom-designed for specific cooling needs.

Step 2: CNC Machining – Precision Enhancement

While the extrusion process forms the general shape, CNC machining is necessary to meet the precise tolerances required in high-performance cooling systems, such as those used in CPUs, power converters, or high-brightness LEDs.

Key CNC Machining Operations:

1. Flatness Milling

The base of the heatsink must make near-perfect contact with the heat-generating component. CNC milling is used to achieve extremely flat surfaces, ensuring optimal heat transfer.

2. Drilling and Tapping

Mounting holes are created through precision drilling and tapping operations. These allow the heatsink to be securely attached to electronic components or casings, which is essential for mechanical stability and thermal performance.

3. Fin Trimming

In some applications, fin height must be adjusted to fit within a defined volume or to improve airflow dynamics. CNC trimming ensures the fins are uniform and optimized for air or fluid flow.

4. Surface Milling

In complex heatsink designs, CNC milling may be used to create stepped, angled, or curved surfaces that better match the geometry of mating parts or airflow paths.

Machining Equipment Used:

* CNC Milling Machines – for flatness and contouring

* CNC Lathes – for cylindrical or radial features

* EDM (Electrical Discharge Machining) – for fine, intricate detailing where mechanical tools are insufficient

The result is a dimensionally accurate, performance-optimized heatsink suitable for direct integration into electronic systems.

Step 3: Surface Finishing – Protection and Performance

After CNC machining, the heatsink undergoes finishing treatments that enhance both its functional and aesthetic properties.

1. Anodizing:

Aluminium is naturally corrosion-resistant, but anodizing further improves this trait by forming a thick, controlled oxide layer on the surface. Anodizing also provides:

* Electrical insulation

* Improved surface hardness

* Color customization for branding or product differentiation

2. Metal Plating:

For specific high-performance applications, the heatsink may be plated with copper or nickel. These materials offer:

* Improved thermal conductivity

* Reduced thermal resistance at interfaces

* Oxidation protection in aggressive environments

Finishing also helps prepare the heatsink for thermal interface materials (TIMs) such as thermal pastes or pads, further ensuring effective heat transfer during use.

Conclusion

The CNC machining aluminium extrusion heatsink process flow is a carefully engineered sequence of manufacturing steps, each contributing to the final product's reliability and efficiency. From extrusion for shape and scale, to CNC machining for precision, and finally to finishing for performance and protection, this workflow ensures that aluminium heatsinks meet the rigorous demands of modern electronics and industrial systems.

By combining traditional forming methods with advanced machining and finishing technologies, manufacturers are able to produce heatsinks that are not only functional but also tailored to the exacting requirements of different thermal management scenarios. Whether used in computers, LED systems, or industrial inverters, CNC-machined aluminium heatsinks remain a cornerstone of efficient heat dissipation.

-

AuthorPosts

- You must be logged in to reply to this topic.