- This topic is empty.

-

AuthorPosts

-

2025-12-23 at 6:14 pm #87305

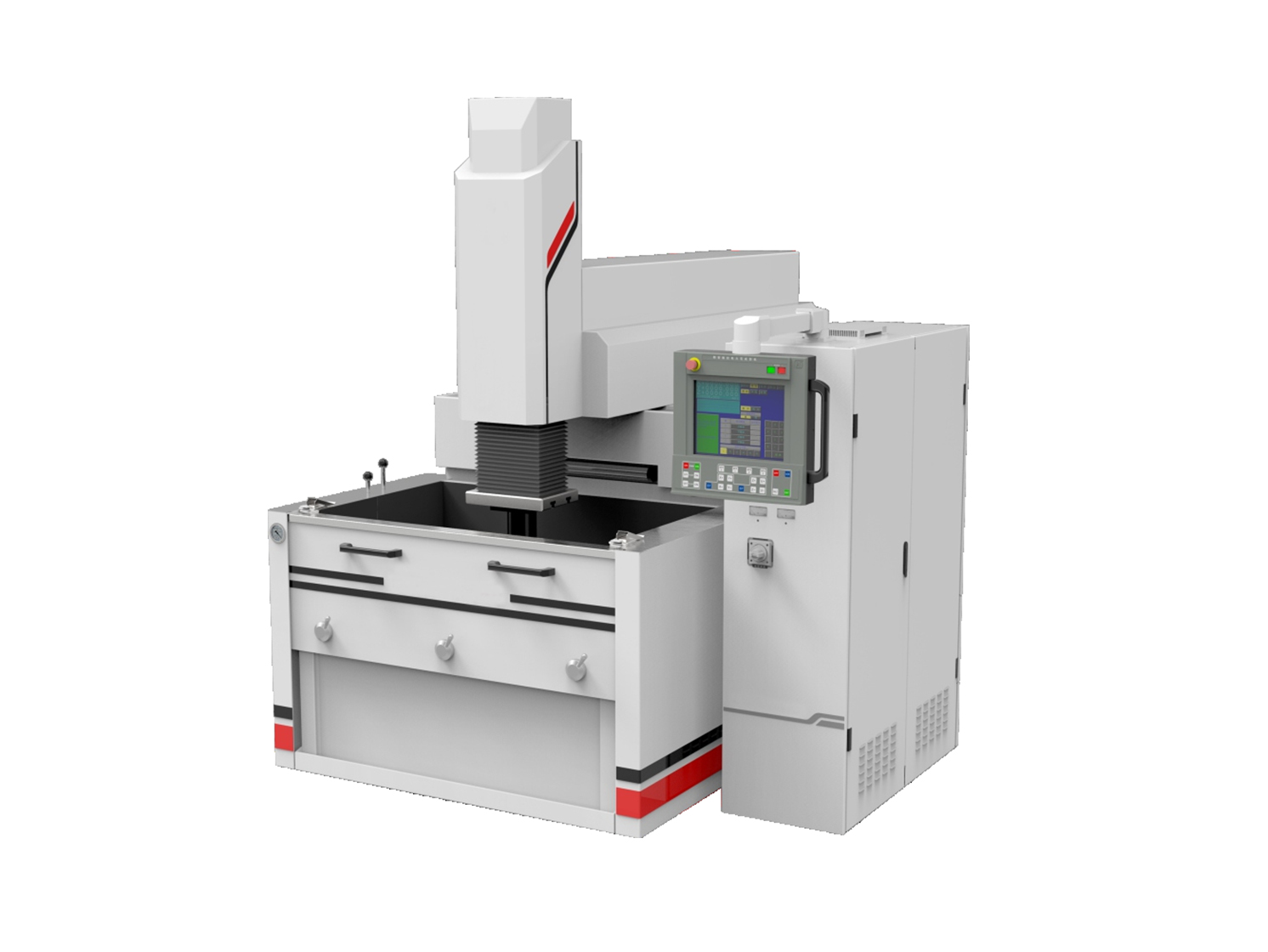

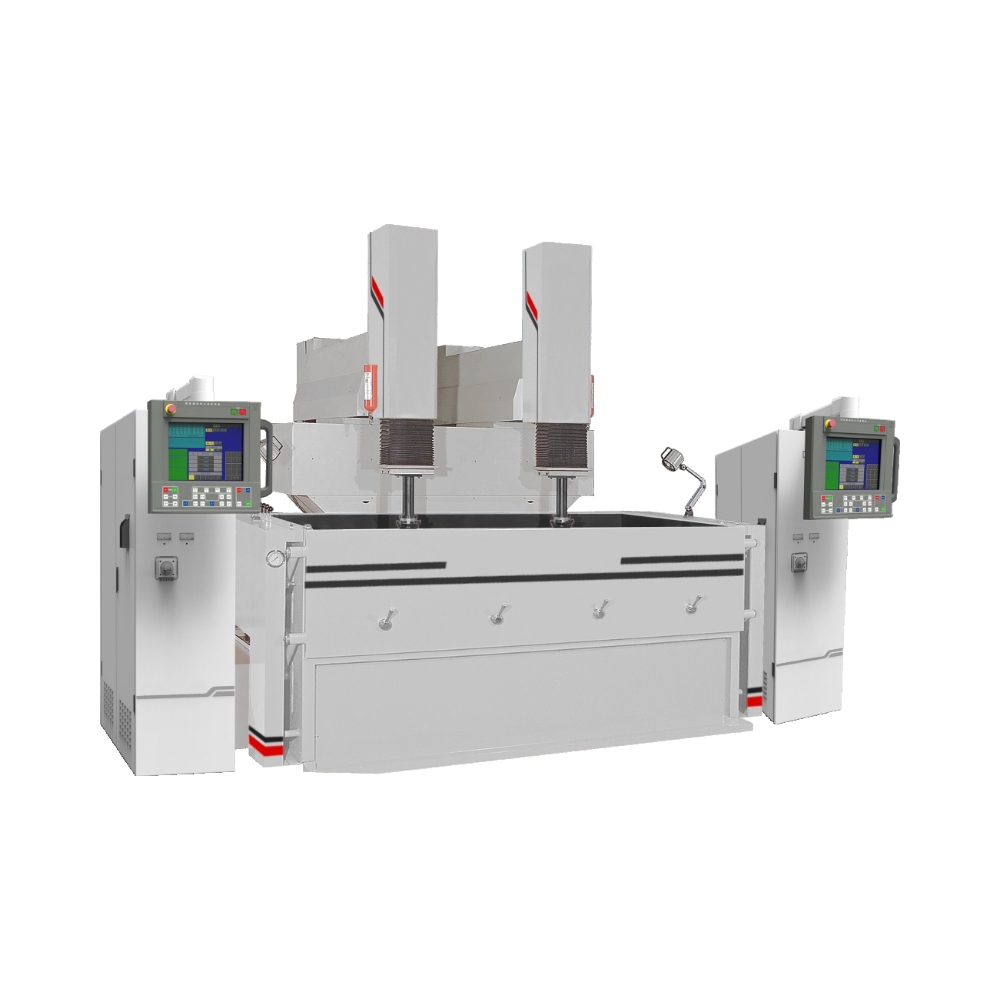

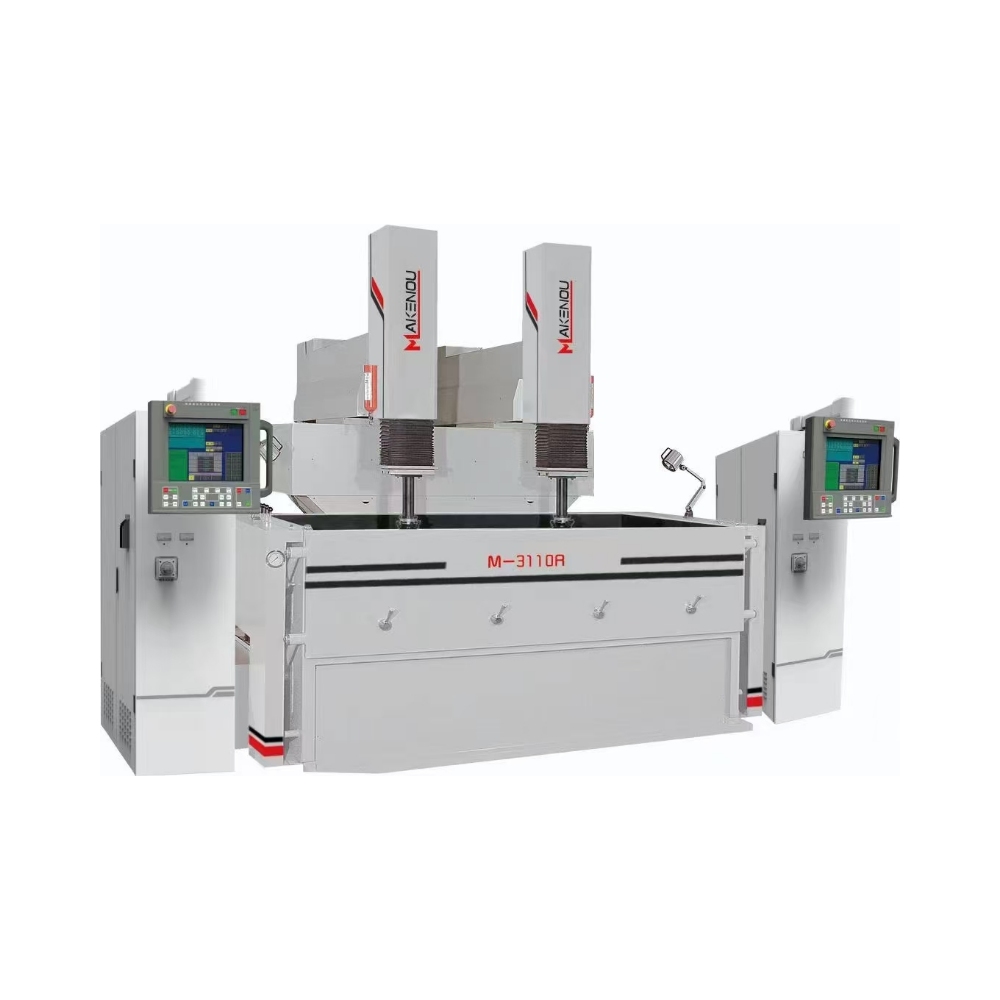

In the fast-evolving world of precision manufacturing, Electrical Discharge Machining (EDM) technology has become a cornerstone for creating complex and high-accuracy metal components. From intricate molds to aerospace parts, EDM has revolutionized how industries handle hard materials and fine-tolerance requirements. Among the leading innovators in this field, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. stands out as a professional manufacturer and supplier of high-quality CNC machining centers, wire-cut EDM machines, electric discharge machines, and milling machines. With years of experience and a strong focus on innovation, the company provides reliable and efficient equipment that drives modern industrial progress.

Understanding EDM Technology and Its Importance

Electrical Discharge Machining, often referred to as spark machining, is a non-traditional metal removal process that uses controlled electrical discharges to erode material from a conductive workpiece. Unlike traditional cutting tools, EDM requires no direct contact between tool and material. Instead, it relies on electrical energy to achieve exceptional precision, especially in materials that are difficult to machine using conventional methods.

This process is particularly effective for hardened steel, titanium alloys, carbides, and other tough metals. By using EDM, manufacturers can create sharp corners, deep cavities, and delicate features that standard machining cannot easily achieve. As a result, EDM plays a vital role in tool and die manufacturing, aerospace engineering, electronics, and the medical device industry.

Key Features of Modern EDM Machines

Today’s EDM machines are far more advanced than earlier models. They incorporate intelligent control systems, robust mechanical design, and efficient power management to deliver consistent precision, energy efficiency, and operational reliability.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. has developed a series of high-performance EDM machines that combine modern technology with practical engineering excellence. Some of their notable features include:

Precision CNC Control Systems – Ensures accurate spark timing, superior machining quality, and smoother surface finishes.

Stable and Durable Construction – A heavy-duty, vibration-resistant frame guarantees long-lasting stability and reliability during extended operation.

High Energy Efficiency – Optimized discharge circuits minimize energy consumption while maintaining consistent cutting performance.

User-Friendly Interface – Intuitive touchscreen controls simplify operation and allow for faster setup, even for complex parts.

Automatic Wire Feeding and Threading – In wire-cut EDM machines, this feature reduces manual intervention, increases productivity, and supports continuous operation.

These innovative, durable, and high-precision machines are designed to meet the demands of both small workshops and large-scale production facilities, providing a perfect balance of performance and cost efficiency.

Applications of EDM Machines Across Industries

EDM machines are known for their ability to create parts that would be otherwise impossible to produce through traditional machining. The technology’s versatility makes it suitable for a wide range of industries, including:

Tool and Die Manufacturing – Producing complex molds and dies with tight tolerances and detailed surface textures.

Aerospace Industry – Crafting heat-resistant turbine blades, engine components, and structural elements.

Medical Equipment Production – Manufacturing micro-components for surgical instruments and implants with mirror-like surface finishes.

Automotive Engineering – Creating precision molds and engine parts that require exact geometries.

Electronics and Semiconductor Fabrication – Producing delicate conductive components and precision connectors.

By offering a wide range of reliable EDM solutions, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. enables manufacturers across these sectors to achieve higher levels of productivity, quality, and precision.

How EDM Machines Work

The principle behind EDM is based on the controlled erosion of metal using electrical discharges. The process takes place in a dielectric fluid, such as deionized water or oil, which acts as both an insulator and coolant. When voltage is applied, a spark jumps the gap between the electrode and the workpiece, generating intense heat that melts and vaporizes a small portion of the metal surface.

This process is repeated thousands of times per second, and the dielectric fluid flushes away the eroded particles. Over time, the cumulative effect of these micro-discharges precisely shapes the workpiece into the desired form.

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. designs its EDM machines with advanced spark control technology, stable pulse power systems, and efficient cooling mechanisms, ensuring smooth cutting performance, uniform material removal, and exceptional accuracy.

Why Choose Suzhou Zhiquan Electromechanical Equipment Co., Ltd.

As a reputable enterprise specializing in precision machinery, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. integrates research, development, production, and sales of CNC machining centers, wire-cut EDM machines, electric discharge machines, and milling equipment. The company’s products are widely recognized for their high precision, robust structure, energy-saving performance, and easy operation.

With a strong commitment to technological advancement and customer satisfaction, Suzhou Zhiquan continuously upgrades its equipment designs to meet the needs of modern manufacturing. Whether you require a high-precision EDM machine for toolmaking or a reliable CNC machining center for production machining, the company offers customized, efficient, and cost-effective solutions that help businesses stay competitive.

Conclusion

EDM machines have redefined the boundaries of precision engineering, making it possible to manufacture components that demand extreme accuracy and intricate detailing. As industries continue to evolve, the demand for reliable, efficient, and precision-engineered EDM solutions will only grow.

With its expertise, advanced manufacturing capabilities, and dedication to quality, Suzhou Zhiquan Electromechanical Equipment Co., Ltd. remains a trusted partner in the field of precision machinery. Their commitment to excellence and innovation ensures that every machine delivers outstanding performance, helping manufacturers achieve higher productivity and superior results.

A Comprehensive Buyer’s Guide to Choosing the Right Full-Function CNC Lathe

http://www.szzhiquan.com

Suzhou Zhiquan Electromechanical Equipment Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.