- This topic is empty.

-

AuthorPosts

-

2025-08-07 at 5:49 pm #86070

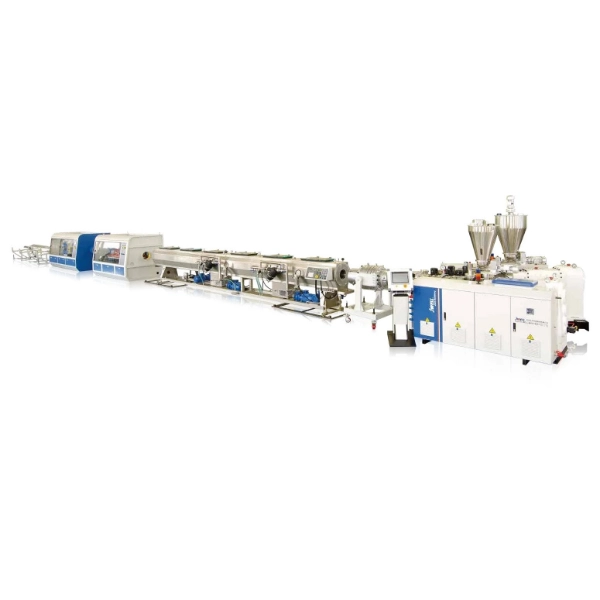

In the modern piping industry, efficiency, precision, and reliability are essential qualities that determine the success of production equipment. In this blog post, Suzhou Jwell will share the performance characteristics of Jwell PVC dual pipe extruder for sale, which stands out for its superior advantages, robust engineering, and productivity-oriented design.

Jwell PVC Dual Pipe Extruder Performance Characteristics

1. High-Output Dual Extrusion System

The most defining feature of the Jwell PVC dual pipe extruder is its ability to produce two pipes simultaneously. This dual-extrusion design significantly improves production efficiency and throughput. Depending on the specific diameter and output requirements of the PVC pipes, two types of specialized twin-screw extruders are available – SJZ65 and SJZ80 models.

* SJZ65 is suitable for smaller diameter pipes or lower production output requirements.

* SJZ80 is ideal for larger diameter pipes or higher volume needs.

Both extruders are designed for stable operation, fast plasticizing performance, and consistent material flow, ensuring uniform pipe quality across dual outputs.

2. Advanced Dual Pipe Die Head Design

The dual pipe die is engineered to evenly distribute molten PVC between two extrusion channels. This ensures uniform wall thickness, consistent pipe diameter, and reduced material waste. The die head's structure enhances the flow balance and extrusion pressure, providing precision forming for each pipe.

Moreover, this design helps shorten the extrusion cycle and increase the speed of plasticization, allowing the system to achieve high output rates without compromising product quality.

3. Independent Double Vacuum Cooling Box

To maintain the integrity and dimensional stability of the extruded PVC pipes, the Jwell line includes a double-vacuum cooling system, which plays a critical role during the shaping process.

* Each vacuum cooling chamber can be controlled independently, providing greater flexibility and precision in adjusting temperature and vacuum settings based on pipe size and extrusion speed.

* The efficient vacuum system ensures rapid cooling and firm shaping of the pipes, preventing deformation and ensuring smooth surfaces.

The modular design also allows for easy adjustments during the production process, contributing to better productivity and lower downtime.

4. Precision Dustless Cutting System

Once the pipes are shaped and cooled, they are cut to length using a high-speed, dustless cutting machine. This component is engineered for accuracy, speed, and cleanliness, avoiding the generation of PVC dust that can affect the final product and working environment.

* The dual-station design allows independent control of each cutter, ensuring seamless operation even during long production runs.

* Cutting length is precise and consistent, minimizing waste and reducing the need for secondary trimming.

5. Pneumatically Rotating Clamps for Enhanced Efficiency

One of the innovative features of the cutting system is the use of pneumatically rotating clamps. This eliminates the manual process of changing clamps when adjusting pipe specifications or changing production setups.

* Automatic clamp rotation improves operational efficiency and reduces labor intensity.

* The clamp system is stable and reliable, ensuring that each pipe is firmly held during cutting, regardless of speed or pipe size.

6. Optional Chamfering Device

For added functionality, the system can be equipped with an optional chamfering device. This tool is used to bevel the pipe ends automatically after cutting, preparing them for easy socketing or connection in downstream applications.

* Chamfered ends reduce manual labor in post-processing.

* It enhances the aesthetic and functional finish of the final product.

7. Intelligent Control and Automation

The Jwell PVC dual pipe extrusion line features an integrated control system that coordinates the operation of all components – from material feeding and extrusion to cooling, cutting, and stacking.

* Operators can monitor real-time parameters through a user-friendly interface, adjusting temperature, speed, and vacuum levels with ease.

* The automation helps to reduce human error, increase operational consistency, and lower overall labor costs.

8. High Durability and Energy Efficiency

Jwell' s design philosophy emphasizes long-term durability and energy-saving performance. All mechanical parts are made with high-quality steel and are precision-machined for stable operation under continuous high-load conditions.

* Twin-screw extruders feature energy-efficient heating systems and optimized torque transmission.

* The production line components are modular and easily maintainable, ensuring reduced downtime and extended service life.

Conclusion

The Jwell PVC Dual Pipe Extruder represents a state-of-the-art solution for efficient PVC pipe manufacturing. Its dual-extrusion capability, precise die head, advanced cooling, and intelligent automation make it a preferred choice for manufacturers looking to maximize output while maintaining superior product quality.

With flexibility for different pipe diameters, seamless operation, and optional add-ons like chamfering, this production line is tailored to meet the diverse demands of the piping industry. Whether for plumbing, drainage, or conduit applications, Jwell' s dual pipe extrusion system delivers performance, reliability, and value.

http://www.jwellplas.com

JWELL -

AuthorPosts

- You must be logged in to reply to this topic.