- This topic is empty.

-

AuthorPosts

-

2025-05-26 at 2:08 pm #84259

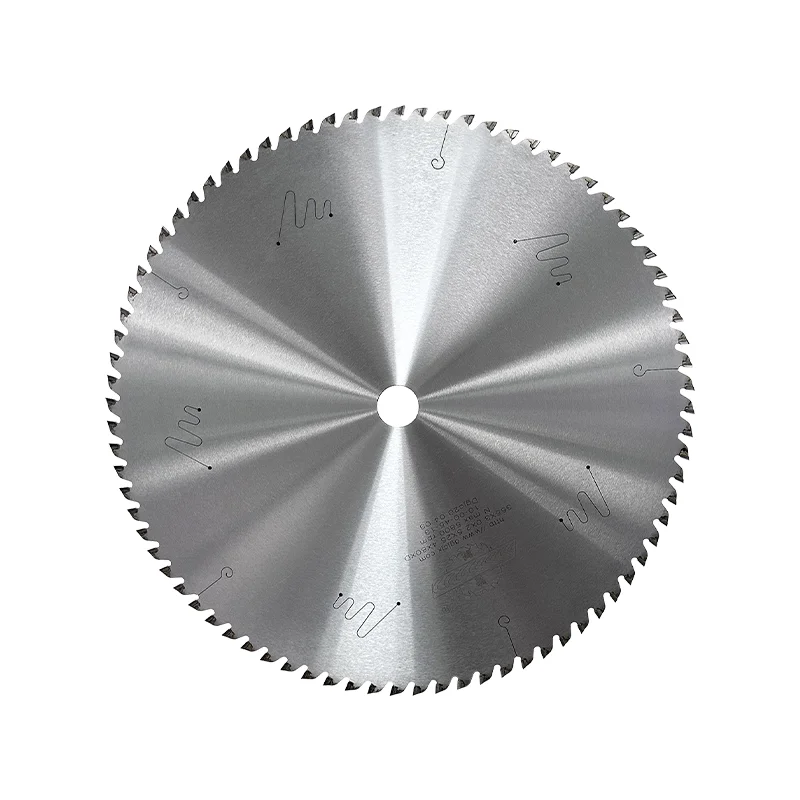

In many fields such as modern industrial manufacturing, metal processing and wood cutting, sawing tools, as one of the key process links, directly affect the cutting efficiency, precision and surface quality of the product. Among the many saw blade materials, tungsten steel (also known as carbide) has become the preferred material for various high-end saw blades due to its excellent hardness, wear resistance and high temperature stability. Choosing a professional tungsten carbide circular saw blade factory not only means obtaining high-quality product guarantees, but also represents long-term stable technical support and after-sales service.

This article will comprehensively analyze why tungsten carbide circular saw blades are trustworthy and the comprehensive competitiveness of professional manufacturers from five aspects: the core advantages of tungsten carbide circular saw blades, industry applications, quality assurance system, purchase recommendations, and the importance of choosing professional manufacturers.

1. Advantages of tungsten carbide circular saw blades

Tungsten carbide circular saw blades, also known as carbide circular saw blades, are high-performance cutting tools made of ultra-fine grain tungsten steel through high-precision welding and grinding technology. They have the following significant advantages:

1.1 Super hardness and wear resistance

The hardness of tungsten steel is as high as HRA 89-93, which is much higher than ordinary high-speed steel. This characteristic enables tungsten carbide circular saw blades to easily cope with the cutting needs of high-strength and high-density materials, and greatly extends their service life.

1.2 High temperature stability

During high-speed cutting, the temperature of the saw blade will rise rapidly. Tungsten steel materials have excellent resistance to thermal deformation, and even at high temperatures above 500°C, they still maintain stable performance and are not easy to anneal and become blunt.

1.3 Sharp cutting and smooth cross-section

Professional tungsten carbide circular saw blades use precision grinding technology, with sharp teeth and uniform tooth shape, which effectively reduces burrs and chipping, ensures smooth cutting cross-sections, and reduces subsequent processing costs.

1.4 Energy saving and high efficiency

Due to low cutting resistance and low heat generation, tungsten carbide circular saw blades can greatly reduce the motor load during use, thereby achieving energy saving effects and are suitable for continuous large-scale operations.

2. Wide range of industry applications

Tungsten carbide circular saw blades are widely used in the following industries due to their strong performance:

Metal processing industry: used for cutting aluminum profiles, stainless steel, copper, carbon steel, alloy steel, etc.

Woodworking industry: used for board cutting, furniture manufacturing, floor cutting, joinery, etc.

Construction industry: used for cutting building materials such as PVC pipes, gypsum boards, aluminum-plastic boards, composite materials, etc.

Automobile manufacturing and rail transportation: plays a key role in the cutting of chassis structural parts and aluminum alloy parts.

New energy industry: precision cutting of emerging materials such as lithium battery casings and solar frames.

Whether it is efficient cutting of metal or non-metallic materials, as long as the working conditions require high-precision and high-life cutting tools, tungsten carbide circular saw blades are almost the first choice.

3. Quality assurance comes from a professional manufacturing system

As a professional tungsten carbide circular saw blade manufacturer, high-quality products are inseparable from a strict quality control system and advanced manufacturing technology. The following are the quality assurance capabilities that regular professional manufacturers usually have:

3.1 Raw material control

All high-quality tungsten steel saw blades are made of high-purity tungsten steel blanks from imported or well-known domestic brands, with uniform particles and stable performance, ensuring the quality of saw teeth from the source.

3.2 Precision manufacturing process

Saw body design: high-strength alloy steel matrix is adopted, and vacuum heat treatment process is carried out to ensure that it is not easy to deform and has high tensile strength;

Welding tooth process: high-frequency welding equipment imported from Germany is used to ensure that each tungsten steel tooth is firmly attached and there is no risk of tooth stripping;

Grinding process: high-precision grinders from Germany and Switzerland are used for tooth profile grinding to ensure accurate and uniform cutting angles and improve sharpness.

3.3 Testing and quality control

Before leaving the factory, each tungsten carbide circular saw blade must pass:

Dynamic balance test

Laser tension test

Accuracy test (runout ≤ 0.02mm)

Welding strength test, etc.

Ensure that each product can run stably on high-speed cutting equipment.

3.4 Environmental protection and safety standards

Professional manufacturers not only pay attention to performance, but also attach importance to environmental protection and safety. Their products comply with ISO9001 quality management system, RoHS environmental protection standards and CE EU certification, and provide customers with a risk-free purchasing experience.

4. Practical suggestions for purchasing tungsten carbide circular saw blades

Faced with a wide range of tungsten steel saw blade brands and models on the market, how to choose a product that suits your needs? Here are some suggestions:

4.1 Clarify the type and thickness of cutting materials

Different materials have different requirements for saw blade tooth shape, tooth pitch and hardness. For example, it is recommended to use a saw blade with a negative rake angle design and a wide tooth pitch design for cutting aluminum, while a staggered tooth design is more suitable for cutting wood.

4.2 Refer to the saw machine speed and installation size

Choose a saw blade that matches the saw machine spindle diameter, speed range and outer diameter to ensure smooth, safe and reliable operation.

4.3 Pay attention to the frequency of use and processing accuracy requirements

Users who use it frequently or have high requirements for cutting accuracy should give priority to high-end customized tungsten steel saw blades to ensure consistent cutting quality.

4.4 Purchase products from professional manufacturers with brand guarantees

Although price is important, quality is more critical. Choosing a manufacturer with a professional background, strong production strength and perfect after-sales service can reduce the cost of later maintenance and replacement.

5. Why choose a professional tungsten carbide circular saw blade manufacturer?

Choosing a professional manufacturer means not only getting a product, but also getting a set of systematic solutions:

5.1 Customized solutions

The tooth structure, tooth density, cutter head material, coating technology, etc. can be customized according to the actual application scenarios of customers to maximize the use efficiency and economy.

5.2 Technical consultation and sample service

The manufacturer has an experienced team of technical engineers to provide usage guidance, saw blade matching suggestions and free proofing services to help customers quickly find the most suitable product type.

5.3 Delivery guarantee and after-sales support

Owned factories, independent production, controllable delivery, and provide complete after-sales support, including answering questions about use, return and replacement, technical tracking and other services.

5.4 Brand reputation and reputation guarantee

Years of industry precipitation, customer witness and stable partners provide a solid foundation for product quality and service guarantee, helping customers maintain their leading edge in the fierce market competition.

The quality of tungsten carbide circular saw blades is directly related to product processing quality, production efficiency and equipment operating costs. Choosing a professional tungsten carbide circular saw blade factory not only means buying a saw blade, but also choosing a comprehensive solution with stable performance, long life and perfect service.

If you need to learn about customized solutions, get sample trials or technical consultation, please contact us – professional tungsten carbide circular saw blade manufacturing experts, looking forward to working with you to create an efficient cutting future!

http://www.chinechernmachine.com

DongGuan Chine Chern Machinery Co.,Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.