- This topic is empty.

-

AuthorPosts

-

2025-12-16 at 6:11 pm #87224

Polyurethane (PU) materials are deeply embedded in modern manufacturing—from car seats and shoe soles to insulation, synthetic leather, electronics, medical components, and transportation systems. As demand for lightweight, durable, and versatile polymers increases, PU producers are seeking more accurate, stable, and flexible manufacturing solutions. Among the critical equipment used in PU production is the low-pressure foaming machine, a system designed to ensure consistent quality and efficient processing.

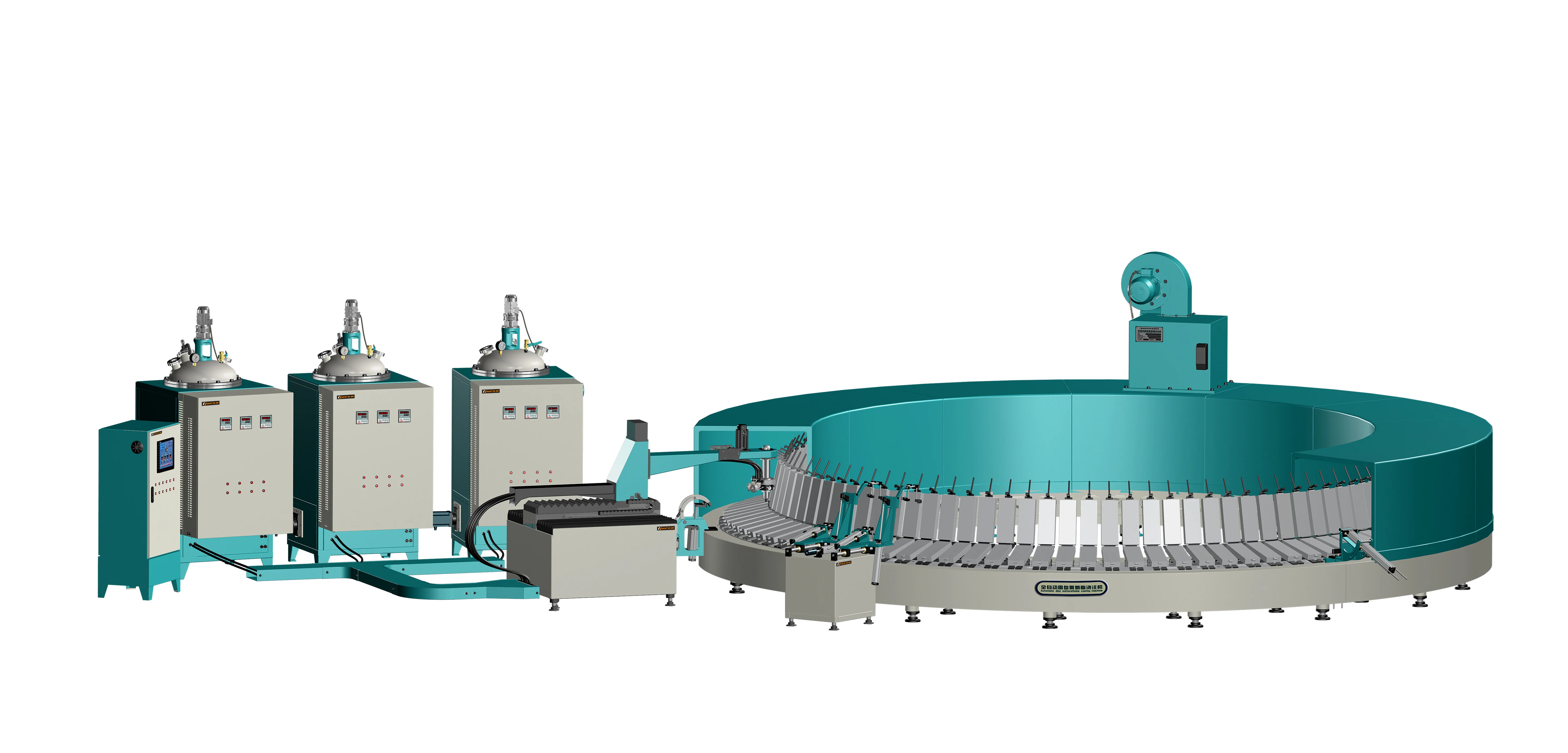

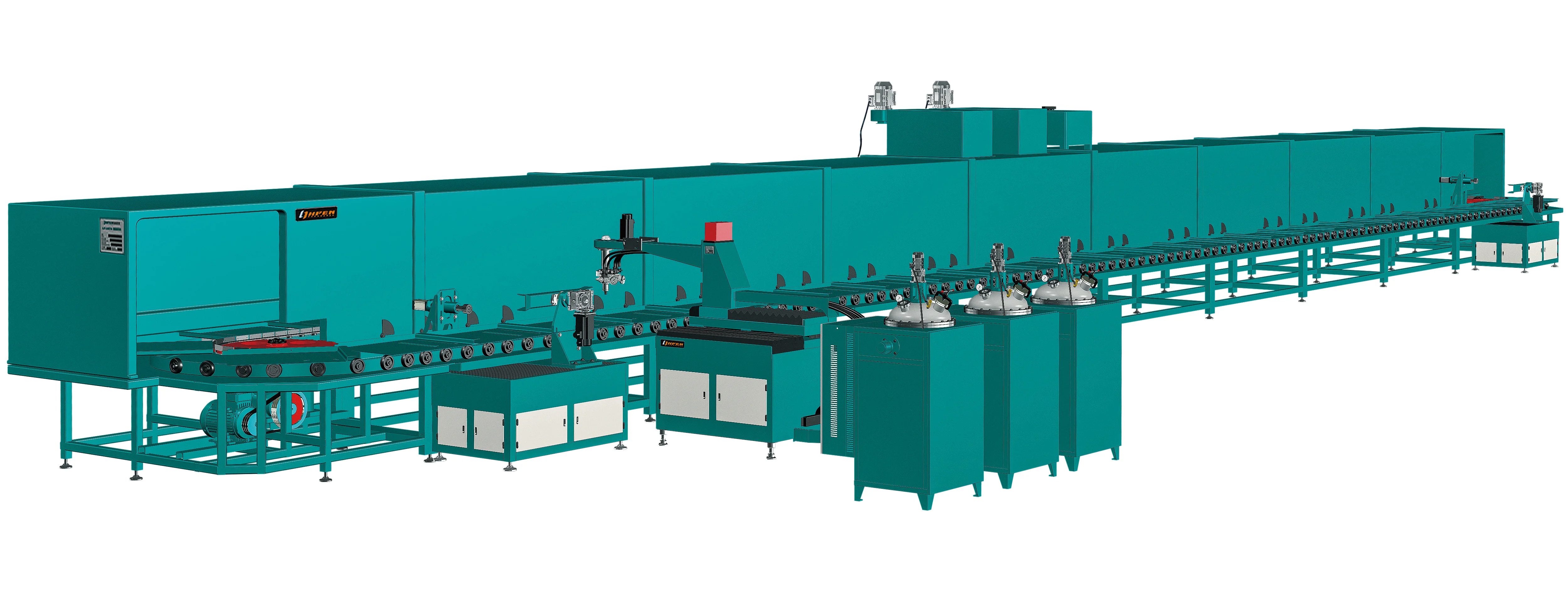

At Haifeng, one of the established manufacturers of PU production equipment and integrated systems, low-pressure foaming technology has become a central pillar in delivering high-performance solutions for automotive, footwear, transportation, R&D chemistry, synthetic leather, electronic components, and many other polyurethane-related industries. To truly understand its value, let’s explore what low-pressure foaming machines are and why they matter so much in today’s PU manufacturing landscape.

Understanding the Function of a Low-Pressure Foaming Machine

A low-pressure foaming machine is specialized equipment that mixes and dispenses polyurethane raw materials—typically polyol and isocyanate—under lower operating pressures compared to high-pressure machines. This mixing process is performed through mechanical agitation, producing a uniform blend that can be poured or injected into molds to form PU foams or elastomers.

Rather than forcing materials together at extreme velocities, the low-pressure method emphasizes consistency, stability, and ease of control. This makes it ideal for applications where quality appearance, foam density, and precision are essential. For sectors such as automotive interior parts, shoe midsoles, electronics encapsulation, and soft foam production, the low-pressure technique offers exceptional flexibility and reliability.

Why Manufacturers Choose Low-Pressure Foaming Systems

PU processors often choose low-pressure foaming machines because of their versatility and cost-effectiveness. These systems are known for their simpler structure, easier operation, and excellent controllability for a wide range of formulations. Their more forgiving mixing style allows for a broader selection of raw materials and additives.

Low-pressure machines also excel in applications requiring manual or semi-automated production. Factories producing small-batch or multi-variety PU products appreciate the machine’s ability to quickly adjust parameters, such as mixing ratio, pouring flow rate, temperature, and reaction time. When switching production lines frequently, low-pressure systems allow manufacturers to maintain stable output without sacrificing product quality.

For companies in developing markets or mid-scale production environments, low-pressure machines provide the perfect balance between performance and affordability while still delivering industrial-grade precision.

Core Advantages Offered by Low-Pressure Foaming Technology

Low-pressure foaming machines bring a wide range of advantages to PU manufacturers.

Some of the most notable include:Enhanced Process Flexibility

They accommodate a variety of PU formulations—rigid foams, flexible foams, elastomers, integral skin foams, and specialty materials used in industries like footwear, synthetic leather, and automotive interiors.

Superior Mixing Stability

Mechanical mixing ensures a uniform blend of polyol, isocyanate, additives, colorants, and blowing agents, resulting in consistent foam cell structure and physical properties.

Easy Maintenance and Operation

The structural simplicity of low-pressure systems means fewer wear parts, easier cleaning, lower maintenance cost, and more user-friendly operation.

Cost Efficiency for Multitype Production

Because the machine handles small and medium batch sizes well, it is ideal for manufacturers who produce multiple PU products or frequently adjust SKU lines.

High Precision in Flow and Ratio Control

Modern low-pressure machines integrate advanced metering pumps, closed-loop control systems, and smart sensors to ensure accurate mix ratios—critical for foam strength, density, and stability.

Key Applications Across PU-Driven Industries

Low-pressure foaming machines support a wide variety of PU product applications, which is why many manufacturers see them as valuable and long-term investments.

Automotive Components

Used for seat cushions, interior panels, headrests, armrests, NVH parts, and energy-absorbing structures.

Footwear Production

Essential for midsoles, insoles, outsoles, and specialty PU foams designed to enhance comfort, resilience, and durability.

Synthetic Leather and Furniture

Ideal for soft-touch PU coatings, flexible foam padding, and integrated foam-skin components.

Electronics and Electrical Components

Used for potting, encapsulation, sealing, and protective cushioning parts.

Transportation and Infrastructure

PU materials provide lightweight, noise-reducing, and vibration-absorbing properties essential for modern transportation systems.

Haifeng’s low-pressure foaming systems are engineered to support all of these sectors with application-specific enhancements, ensuring customers benefit from precise control, stable performance, and long-term equipment reliability.

How Haifeng Helps PU Manufacturers Elevate Their Production Processes

Haifeng has grown into one of the recognized manufacturers of polyurethane production equipment and integrated systems. With decades of experience in PU machinery design, engineering, and R&D, Haifeng has built a reputation for delivering efficient, stable, and high-quality foaming solutions tailored to the needs of multiple industries.

Haifeng’s low-pressure foaming machines stand out due to:

-

Intelligent metering and ratio control

-

Energy-efficient mixing technology

-

High-quality components for long-term durability

-

Customizable pouring heads and molds

-

Advanced temperature and flow monitoring

-

Compatibility with diverse PU formulations

-

Tailor-made system design for automotive, footwear, chemical labs, transport, and other industrial needs

By integrating automation, digital control, and precision engineering, Haifeng helps manufacturers increase production stability, reduce waste, and enhance end-product performance.

Conclusion

A low-pressure foaming machine is far more than basic mixing equipment—it is the backbone of countless PU production workflows across multiple industries. From flexible foams and elastomers to automotive parts, electronics, and footwear components, the versatility and efficiency of low-pressure foaming make it a preferred choice for many manufacturers.

As one of the industry’s respected PU production equipment and system manufacturers, Haifeng continues to innovate low-pressure foaming solutions that deliver consistency, precision, and long-term reliability. Whether a company is scaling up production, diversifying PU product lines, or improving quality control, a well-engineered low-pressure foaming system can significantly elevate performance and competitiveness.

http://www.haifeng-automation.cn

Haifeng -

-

AuthorPosts

- You must be logged in to reply to this topic.