- This topic is empty.

-

AuthorPosts

-

2025-08-04 at 2:12 pm #86034

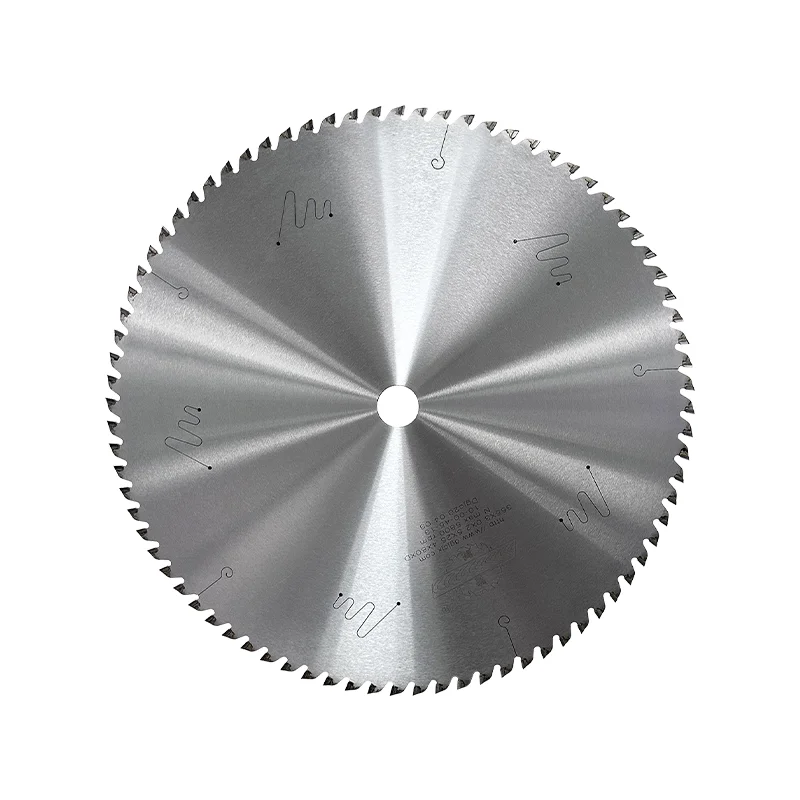

Tungsten carbide circular saw blades are widely used in the cutting of metals, woods and composite materials due to their high hardness, wear resistance and good cutting performance. However, in actual use, many users will encounter problems with unsatisfactory cutting effects of tungsten carbide circular saw blades, such as unsmooth cutting, many burrs, rough cutting surfaces, severe heating of saw blades and even breakage. This article will analyze in detail the common reasons for poor cutting effects of tungsten carbide circular saw blades from multiple angles, and put forward corresponding solutions to help users improve cutting quality and extend the life of saw blades.

1. Material and structure problems of tungsten carbide circular saw blades

1.1 Tungsten steel material quality is not up to standard

Tungsten steel (hard alloy) is a composite material made of metal elements such as tungsten and cobalt through powder metallurgy technology. Its hardness and toughness directly affect the cutting performance of circular saw blades. If the purity of tungsten steel material is insufficient or impurities are mixed in, the hardness will be reduced, the saw blade will be easy to wear and break, and the cutting effect will be significantly reduced.

1.2 Unreasonable saw blade design

The design parameters of tungsten carbide circular saw blades, such as tooth shape, tooth pitch, number of teeth and thickness, play a decisive role in cutting performance. If the tooth shape is not suitable for the material being cut, or the tooth pitch is too dense or too sparse, it will affect the smoothness and quality of cutting. For example, when cutting hard metal, a larger tooth pitch and thicker saw blade should be used, whereas when cutting thin plates or soft materials, thinner teeth and thin blades should be used.

1.3 Poor welding process

Tungsten steel teeth are usually fixed to steel plates by brazing or laser welding technology. Poor welding process can easily cause the teeth to loosen, fall off or break, which directly affects the cutting quality and safety.

2. Use environment and operating factors

2.1 Inappropriate saw blade speed

Tungsten carbide circular saw blades have certain requirements for the saw machine speed. Too low speed will lead to low cutting efficiency, the saw teeth cannot fully exert their sharpness, and the cutting surface is rough; too high speed will easily cause the saw blade to heat up, burn, and even wear or break quickly. Saw blades of different specifications and materials have corresponding recommended speed ranges, which must be strictly followed when used.

2.2 Improper feed speed

When cutting, the feed speed is too fast, the saw blade is overloaded, and the teeth cannot smoothly cut into the material, resulting in cutting jams, cracked saw teeth, and even saw blade breakage. If the feed speed is too slow, the cutting efficiency is low, the saw blade wear is aggravated, and the saw blade is easily damaged due to local high temperature.

2.3 The cutting material and the saw blade do not match

The hardness, toughness and structure of different materials vary greatly. If the tungsten carbide circular saw blade is not reasonably selected according to the cutting object, the cutting effect will inevitably be unsatisfactory. For example, carbide teeth are designed for steel cutting. If they are used to cut aluminum alloys or plastics, the saw teeth may become blunt quickly and the cutting quality will decrease.

2.4 Insufficient ambient temperature and cooling and lubrication

Tungsten carbide circular saw blades generate a lot of heat during high-speed cutting. If the cooling and lubrication are not sufficient, the temperature of the saw blade rises rapidly, causing the tungsten steel teeth to burn, the cobalt binder to soften and fall off, the wear is accelerated, and the cutting quality is reduced.

3. Inadequate maintenance

3.1 Saw blades have not been cleaned for a long time

If the saw blade surface and tooth gap accumulate chips, oil or resin, it will reduce the cutting efficiency, cause uneven cutting surface or even block the saw blade, affecting the cutting effect.

3.2 Saw blades are seriously worn and not replaced or sharpened in time

After a period of use, the sharpness of the tooth tip and tooth surface of the tungsten carbide circular saw blade will decrease. If it is not sharpened or replaced in time, the cutting resistance will increase and the cutting effect will naturally deteriorate.

3.3 Incorrect installation of saw blades

If the saw blade is not tightened in place during installation, or the installation direction is wrong, it will cause the saw blade to be eccentric, the vibration will be aggravated, the cutting accuracy will be reduced, and the saw blade will be easily damaged.

4. Problems with equipment and auxiliary facilities

4.1 Insufficient rigidity or poor maintenance of the saw machine

Insufficient rigidity of the saw machine, excessive vibration of the machine tool during operation, will affect the cutting trajectory of the saw blade, resulting in uneven cutting and rapid damage to the saw blade. Inadequate equipment maintenance, such as wear or poor lubrication of guide rails and bearings, will also cause similar problems.

4.2 Imperfect cooling system

Some cutting tasks require water cooling or oil cooling system, and the cooling effect directly affects the life of the saw blade and the cutting quality. Blockage of the cooling system and poor quality of the coolant will cause abnormal heating of the saw blade.

5. How to avoid poor cutting effect of tungsten carbide circular saw blades?

Choose regular brands and high-quality materials: Purchase tungsten carbide circular saw blades that have undergone strict quality control to ensure that the material is pure and the welding is firm.

Reasonably select saw blade models and parameters: According to the cutting material, thickness, and saw machine specifications, select tungsten carbide circular saw blades with appropriate number of teeth, tooth shape, thickness and diameter.

Strictly operate according to the manufacturer's recommended parameters: strictly control the speed, feed speed and cutting depth to avoid blindly speeding up the cutting rhythm.

Regularly maintain and service the saw blade: clean the saw blade regularly, sharpen or replace it in time to ensure that the saw blade is sharp and prolong its service life.

Improve the cutting environment and cooling conditions: be equipped with a complete cooling and lubrication system to ensure that the temperature of the saw blade is stable when working.

Train operators: improve operator skills, correctly install saw blades, and standardize operating procedures.

As a high-performance cutting tool, the cutting effect of tungsten carbide circular saw blade is directly related to the processing quality and production efficiency. There are many reasons for poor cutting effect, including the material and design problems of the saw blade itself, as well as the influence of the operating environment, equipment maintenance and usage habits. Only by starting from multiple links such as material selection, design, operation, and maintenance, and using tungsten carbide circular saw blades scientifically and rationally, can its best performance be exerted and the ideal cutting effect be obtained.

If you encounter specific problems in the process of using tungsten carbide circular saw blades, it is recommended to contact professional technical support in time to obtain targeted solutions to avoid the impact of saw blade problems on production progress and product quality.

As a professional circular saw blade wholesaler, Chine Chern has always been committed to providing customers with high-quality tungsten carbide circular saw blade products. With years of industry experience and strict quality control, it ensures that each circular saw blade has excellent hardness and wear resistance to meet various cutting needs. At the same time, the company pays attention to after-sales service and technical support to help customers solve various problems encountered during use and ensure the smooth progress of cutting operations. Choosing Chine Chern, you will get stable and reliable product quality and professional cooperation experience, which will help you continuously improve your production efficiency and processing quality.

http://www.chinechernmachine.com

chinechernmachine -

AuthorPosts

- You must be logged in to reply to this topic.